Custom Made Case Notary Public Stamp Seal Press Pt 2

Night time workshop goings ons!

- Fitting the base

- Fitting the Lid

- Shaping the Raised Panel

Some more work in progress photos of the Stamp/Seal box. In this post I will show the steps involved in fitting the base and lid into the slots as well as fitting the solid brass plaque into the top.

It’s little things like this that take the extra time — I like to sneak up on the fit rather than create a slot that’s slightly too wide or too deep, there’s nothing worse than getting half way through the glue up only to find something is slightly out of line or the base bottoms out in the slot and throws the whole thing out of square.

It can be very hard to correct once you have glue on the tight fitting dovetails, so preparation is key.

The base piece should be a perfect fit and square so this will help align everything when it comes to assembly of the dovetails with glue for the final time.

Fitting the Lid

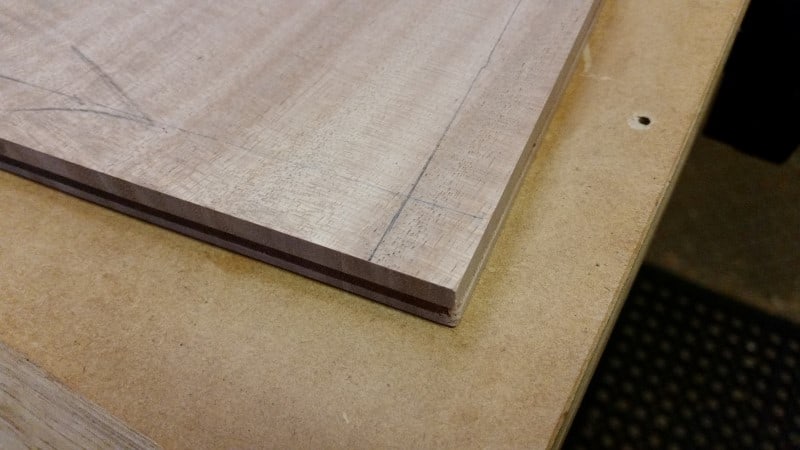

The bottom slot needs to be just over 4mm to accept the Victorian Ash ply base. The top slot is bang on 3mm to mate with the lid slot for the raised panel lid pictured below.

The stepped-raised-panel-lid is solid timber construction so allowing room for expansion and shrinkage is critical — unlike the base piece which will be snug fit allowing only for a thin smear of glue.

Both of these trees came down in Cyclone Yasi – the Queensland Maple will soon be married with the Blackbean for life and I thought to myself I wonder if these trees were together?

— They were in the same region, perhaps they knew each other while growing up! 😊

Now for the fun part…

Shaping the raised panel lid.

This is where grain direction needs to be taken into account when using hand planes (or any other tool for that matter), as you can see the bookmatched lid pieces both have grain in opposite direction so I had to come in from each end to avoid tear-out in this interesting fiddleback section — planing toward the centre only, not towards the outer edge!

The exact angle of the bevel is not important, I just do it by eye until I get a nice even match in bevel width and a 45 degree corner ridge.

I had to stop and sharpen my plane before finishing with a much finer pass over the bevel to smooth out any tear out and bring it up to the pencil line. This Maple can be tricky in places. It’s the first time I’ve worked with such a fussy piece but the results in the lid when finished will be well worth the effort.

Next post I will show how I fit the solid brass plaque into the raised panel lid by cutting a recess with a chisel.

Box Features

- Rescued timber from the cleanup after Cyclone Yasi

- Rare Queensland Maple highly figured

- Body of the case is Black-bean? (I think) – also from Cyclone Yasi.

- Hand cut dovetail joinery

(shown in future blog posts)

- Gibson Guitar Case Handle

- Hand stitched leather

- Brass Mounts

- Solid Brass Hinges (leaf hinge)

- Solid Brass Lock (Mortise Fit)

Test comment

This blog will be up and running again one day, I promise! 🙂